At a facility in the heart of Champagne, the winemaker uses time-tested methods and updated tech to create its signature bubbly.

Since Joseph Krug started his eponymous Champagne house in 1843, the maison had been making its annual Grande Cuvée release in the region’s largest city, Reims. Last year, the company moved to a more modern facility in the village of Ambonnay. The cutting-edge winery—named Joseph, after its founder—is more than 100,000 square feet in size but was designed to fit in with the tiny commune’s traditional architecture. (Home to fewer than 1,000 people, it boasts a church that dates to the 11th century.) But Krug’s new space also abuts one of the world’s finest vineyards, Clos Ambonnay, which is significant. Cellar master Julie Cavil tells Robb Report that in addition to its being the source of Krug’s exquisite single-vineyard bottling of the same name, “there is a drop of Ambonnay in each edition of Krug Grande Cuvée.”

This wine, one of six prestige cuvées Krug produces, is a master class in crafting Champagne—and the new building’s soaring wood ceilings and colossal plate-glass windows provide an apt setting for its development. Using an age-old method, Krug sources grapes from 120 plots across the region to create each year’s edition, blending their juices with wines from up to 10 vintages. And technological advancements at the state-of-the-art edifice allow Cavil and her team to track each plot from vineyard to bottle. There’s even a specially designed app called Black Book that has replaced the paper ledgers Krug used for over 150 years. Like the building, the Grande Cuvée combines tradition and modernity to stunning effect: The resulting dram—renowned for its complex layers of flavor and long-lasting finish—can command $1,000 a bottle on the secondary market. Here’s how it’s made.

1. Harvesting the Best

Pinot Noir, Pinot Meunier, and Chardonnay grapes are harvested from across Champagne. Vineyards in villages such as Les Riceys, Verzenay, Montgenost, Mesnil, and Ambonnay offer a diverse array of terroirs, which contributes to the cuvée’s beloved mosaic of flavors.

2. Pressing the Juice

After selecting the best grapes, winemakers gently press them lot by lot to express the must, the fresh juice that will be transformed into wine. “A single plot can sometimes be no larger than a small garden,” Cavil says, which means this stage is an exacting process.

3. Oak-Barrel Fermentation

The addition of yeast, which consumes the must’s natural sugar to create alcohol, is what turns the juice into wine. The resulting liquid from each lot is fermented separately in one of 4,300 oak barrels for up to two weeks.

4. Sealed in Steel

When fermentation is complete, still wine is moved from its barrels to one of 330 stainless-steel vessels in Joseph’s tank cellar. It will remain in these airtight neutral vessels, often for years, until Cavil’s team deems it ready for blending.

5. Plots That Blend

“At Krug, each plot of vines is like an individual musician, and each year, the score is different,” Cavil says. These “scores” determine which wines make it into the final blend. In addition to 250 wines from the current or “base” vintage, Krug selects from 150 reserve wines to include in the Grande Cuvée’s final blend.

6. The Bubbles Form

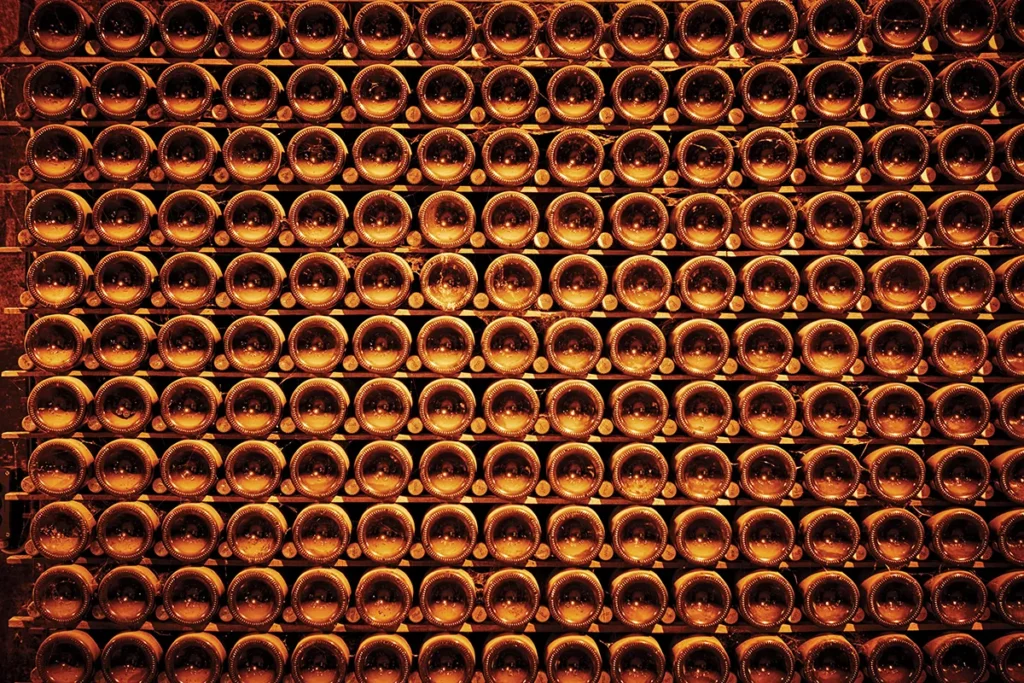

The finished blend and liqueur de tirage (a sugar and yeast solution made with the still wine) are combined and bottled. This is when the magic happens: As yeast consumes the additional sugar, it releases carbon dioxide, creating Champagne’s characteristic bubbles. The bottles will mature in limestone cellars beneath the House of Krug in Reims for six years. Toward the end of this period, Cavil’s team starts tasting the contents to determine whether additional time is required.

7. Disgorgement

As final maturation approaches, bottles are placed mouth down in special riddling, or remuage, racks and rotated a one-quarter turn each day over four to six weeks. This process gently dislodges any sediment created by spent yeast cells. The bottles get their final corks (held in place with a wire cage called a muselet) after this yeast is disgorged.

8. Golden Touch

Finished bottles remain in Krug’s cellars for one more year. Prior to release, a special committee tastes the Grande Cuvée to ensure its quality. Only then are the brand’s signature gold labels applied.